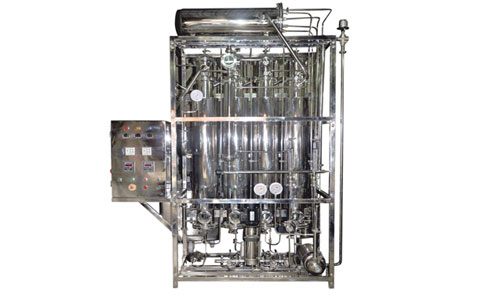

Multicolumn Distillation Plant

Applications :

Salient Features :

- Output water compliant to USP/BP/IP norms

- Pure, sterile and pyrogen free distilled water

- Compact space saving design

- Lab Model available

- High operational reliability

- Meets GMP and FDA norms

- Easy and silent operation

- Excellent energy efficiency

- Easy to maintain and operate

- Fully automatic operation

- High degree of finish

- Auto dumping of sub-standard distillate

- Special sanitary fittings

Operation

Multi-stage distillation uses a number of water evaporators arranged in series with stepwise reducing temperature and pressure conditions.

The system works on the principle of inter-stage heat exchange and use intrinsic heat to supplement consumption need of heating energy and cooling water.

Due to surface film evaporation, a part of the feed water on the inside of the heat exchanger tubes in converted to steam. A controlled amount passes through the column which results in rapid cooling of boiler steam (external source) thus creating vapours at high velocity under pressure. Because of centrifugal force, the vapours rising through the entrained section are subjected to a 180o turn.

The pure vapour rises upward through a vertical section outside the heat exchanger(inner column) due to spirel motion. The unique centrifugal separation removes impurities such as pyrogens and endotoxins which flow out as they are blown down. The purified steam then moves towards upper end of the column. Condensing vapour from the previous stage is used as the heat source for the next. Since system needs heat to vaporize only 30 % of the feed water, heating energy requirement is reduced by 70%.

Consumption data

| Steam Pressure | Steam Consumption(kg) | Feed Water(L) | Cooling Water(L) | Output | |||||

|---|---|---|---|---|---|---|---|---|---|

| Model | 150 L | 300 L | 150 L | 300 L | 150 L | 300 L | 150 L | 300 L | |

| At 3 bar | 50 | 98 | 171 | 345 | 130 | 300 | 150 | 300 | |

| At 4 bar | 60 | 121 | 206 | 415 | 170 | 380 | 180 | 350 | |

| At 5 bar | 70 | 145 | 240 | 485 | 200 | 400 | 200 | 400 | |

| At 6 bar | 80 | 165 | 265 | 530 | 230 | 460 | 230 | 450 | |

| Steam Pressure | Steam Consumption(kg) | Feed Water(L) | Cooling Water(L) | Output | |||||

|---|---|---|---|---|---|---|---|---|---|

| Model | 500 L | 1000 L | 500 L | 1000 L | 500 L | 1000 L | 500 L | 1000 L | |

| At 3 bar | 130 | 240 | 575 | 1150 | 250 | 900 | 500 | 1000 | |

| At 4 bar | 160 | 300 | 695 | 1390 | 325 | 1000 | 600 | 1200 | |

| At 5 bar | 192 | 355 | 795 | 1600 | 395 | 1100 | 700 | 1400 | |

| At 6 bar | 220 | 455 | 390 | 1955 | 440 | 1250 | 760 | 1600 | |

Quality Focussed

Multi Column Distillation Plants (WFI Plants) are exposed to extreme operating conditions. Our WFI plants are fit for extreme temperature and pressure. We ensure quality, right from Design to Installation and Commissioning.

- All materials of construction are tested to ensure material quality. Test Certificates will be provided.

- All instruments are tested and calibrated accurately to measure the temperature, pressure and conductivity at critical points.

- Certificate of compliance and quality issued for all Pumps, Valves, and Fittings.

Customised Solutions

- Distilled water equipment requirements can vary from application to application.

- Need distillation solutions for low capacity?

- Pure Steam and Distilled water in the same unit?

- We understand the flexibility you need in your equipment.

- We design your Multi Column Distillation Plant to meet your individual specifications.

- We also support manufacturing of storage tanks.

- Of course, you will receive comprehensive support on the validation documentation (DQ, IQ, OQ) for your WFI set-up from us.